Hello! September has come but the days continue to be hot! We hope you are doing well!

Continuing from last month, we would like to introduce more of the history of rice polishing. In our last article, we shared about rice milling by foot-power and by waterwheel, which utilized the river current in the Edo period (1603-1868). In this post, we’d like to introduce the modern rice polishing methods which were used after the Meiji Restoration (1868).

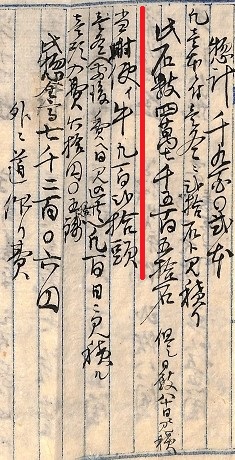

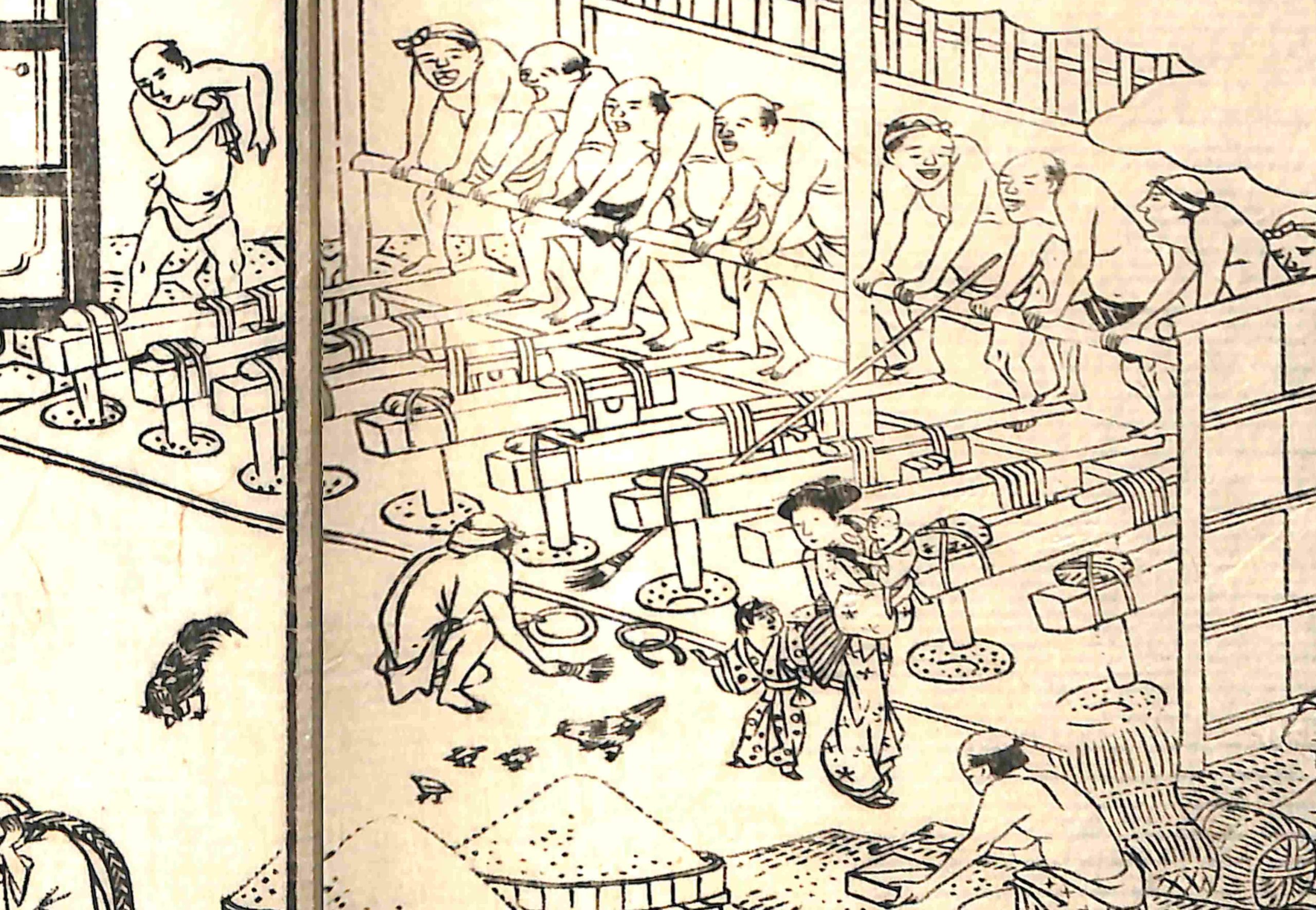

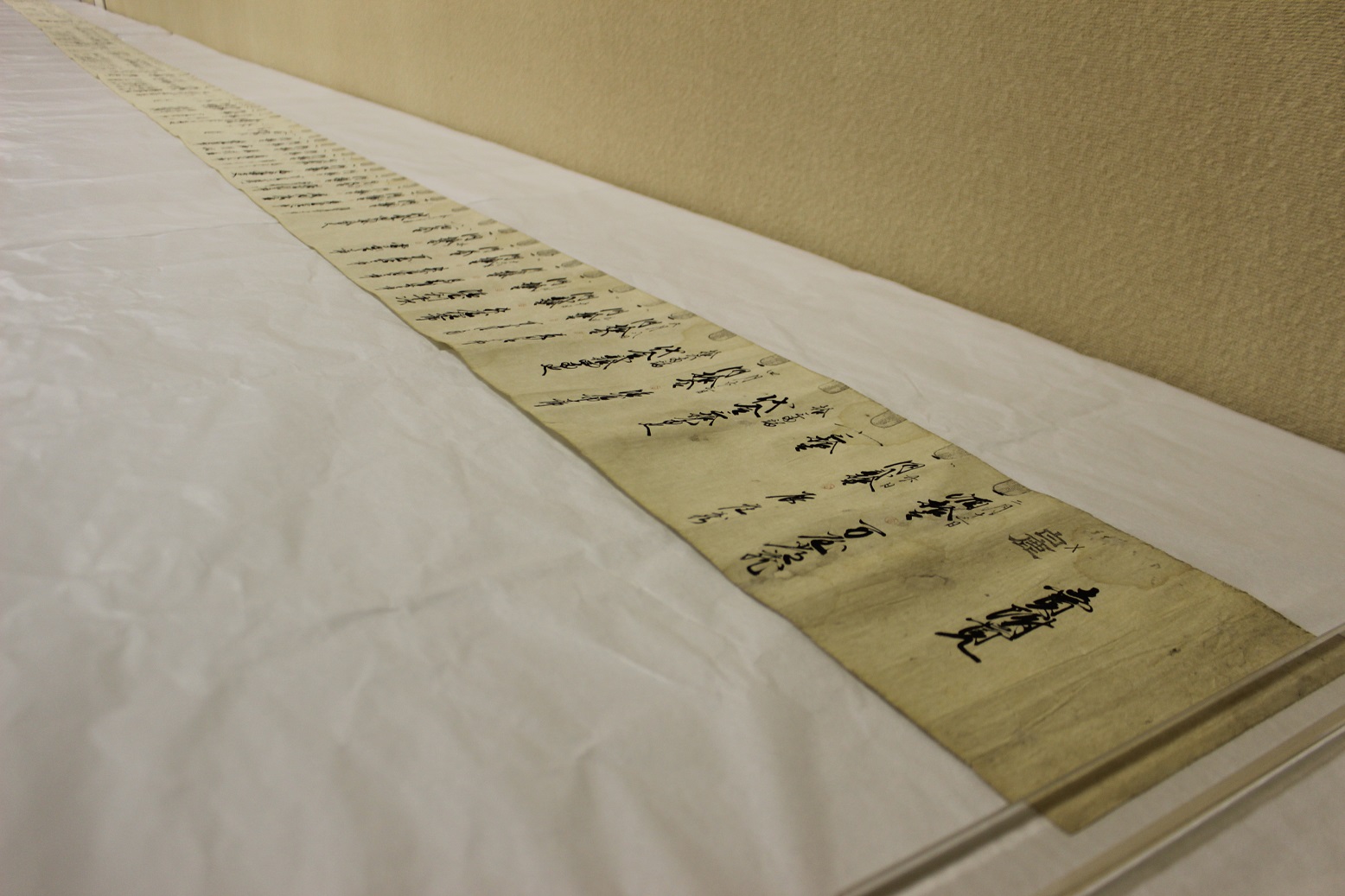

Rice milling by foot-power and waterwheel continued even after the Meiji Restoration. However, because foot-power relied on human labor, it limited the amount of rice that could be milled at one time. Waterwheel rice milling could not continue when the amount of river water decreased due to the lack of rain. Because of these limitations, modern technology of rice polishing using the steam engine, which was developed in the West, was introduced to Japan. During that time, the steam engine had already been well known as motive power for vessels and steam locomotives. It was around 1886 that the steam engine began to be utilized for rice polishing in Sakai (present-day Sakai City, Osaka Prefecture). In 1888, Tatsuuma Kijuro, a sake brewer in Nishinomiya, adopted this technology for sake brewing in Nishinomiya. At first, workers were concerned about the contamination of black smoke to their sake. In practice, however, there was no problem and gradually more and more sake brewers adopted the steam engine to their rice polishing.

When the waterwheel rice milling was in full swing, milled rice was transported by ox carts from the upstream areas of the river to the sake breweries by the seaside. The town of Nishinomiya was full of ox carts during the peak seasons. There were many high waterways connecting the river current to the waterwheels. These pre-modern scenic views gradually disappeared with the appearance of the rice milling plants with steam engines which were constructed next to the sake breweries. The scenery of the town was forever changed along with the evolution of industrial technology.

The technology of rice polishing further developed and eventually machine polishing became the main method, replacing the mortar and pestle method of milling. The first rice polishing machine was invented in England, thereafter another machine utilizing the coffee bean peeler was invented in the U.S.A. In Japan, the first rice polishing machine was a German one which was imported by British businessman Edward Hazlett Hunter who launched a rice polishing business in Kobe in 1885. He is still well-known for the Hunter-zaka avenue in Kitano, Kobe. The first domestic “Power Driven Rice Milling Machine” was invented by Satake Riichi in Hiroshima in 1896. While he continued to make improvements to his machines, other inventors such as Shimizu Hirokichi and Imahashi Yoshimatsu also developed their own machines and joined the development race. In this way, domestic vertical rice polishing machines were developed and became common nationwide. By the early 20th century, almost every sake brewery had rice polishing machines of the equivalent level.

Today, the technique of rice polishing machines has been developed further compared to the techniques in the early 20th century because rice needs to be polished up to 50% in order to make Dai Ginjo sake. In recent years, technologies have been further developed to control the shape of milled rice.

We think it would be nice to enjoy delicious sake while appreciating the development of rice polishing technology!

Please check back for next month’s article!

Well-polished white rice is needed for sake brewing!