Hello! It feels like autumn is coming. So, the season for making sake is setting in. Oke-shi who introduced in the last Sake Talk started to repair vats in the sake brewery from this time onward.On the other hand, since the Meiji era (1868-1912), the sake brewing industry has become mechanized, so the works of oke-shi are seldom seen. This article focuses on the transition of wooden tools to machines highlighting some advertisements in journals about sake brewing.

When the Brewing Society of Japan was established in January 1906, the journal of it was published the same year. This journal contains advertisements from sake brewers and they let us know about latest and most popular machines of the time.In the Sake Museum, we have the journal published on March 10, 1911, so let’s see the advertisements in this issue.

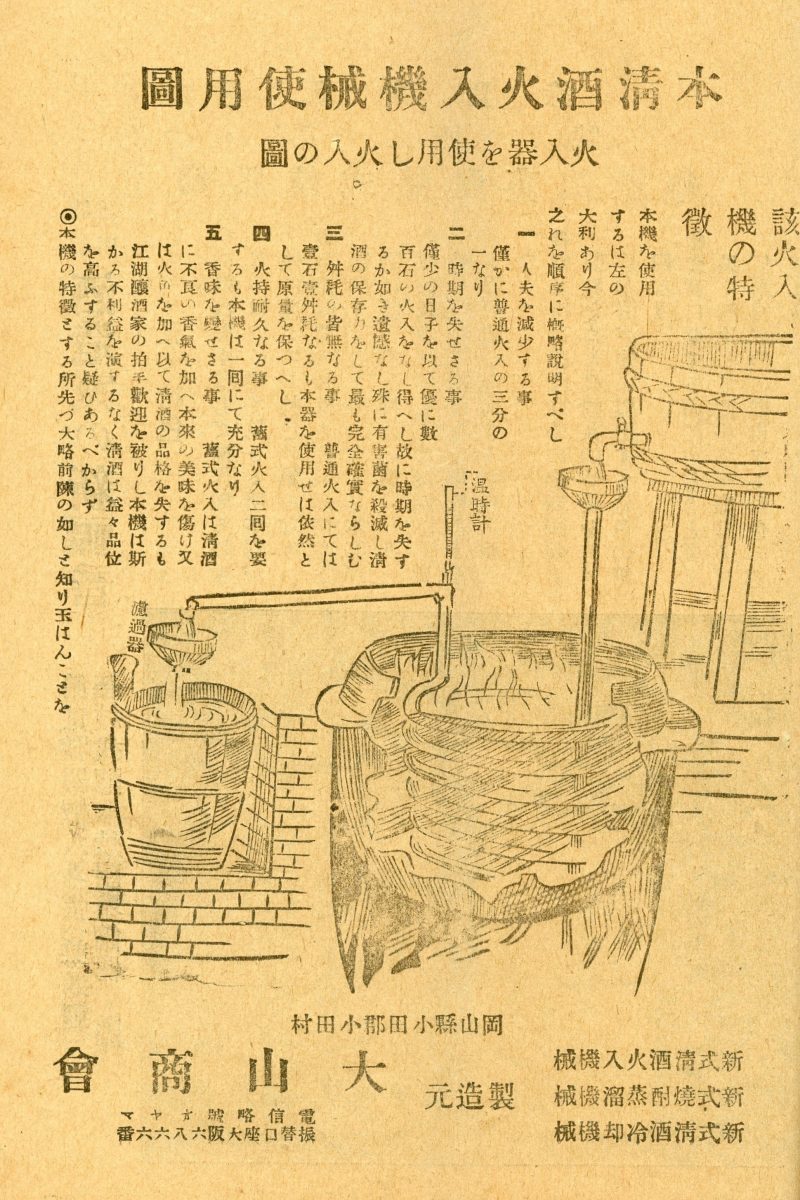

In this issue, advertisement about pasteurizer is placed. Pasteurizer is a machine used to heat and sterilize sake. In the Edo period (1603-1868), sake was heated in iron caldrons over a fire, but craftsmen has to coat inside of the caldrons with lacquer to protect the quality of sake from iron content. Therefore, the pasteurizer was invented. It called “jya-kan (snake pipe)” because of the shape of the copper pipe wound around it like a snake.

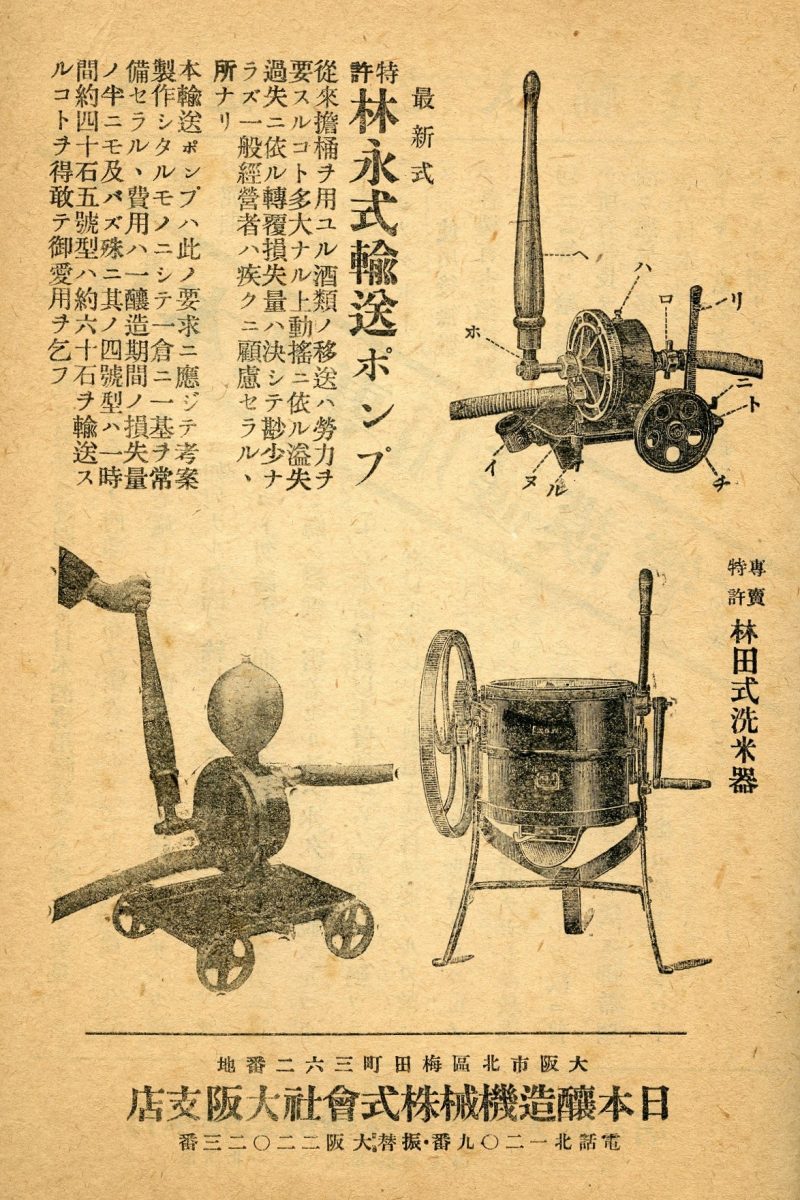

At first, sake was passed through pipes which were made of tin. And then, they were put into boiled water and sake was heated and sterilized. Also, pumps were used to transport sake into pipes. The journal on 1919, there is an advertisement of pumps. Thus, the ways to transport liquids such as sake and water were also streamlined from the manpower using vats.

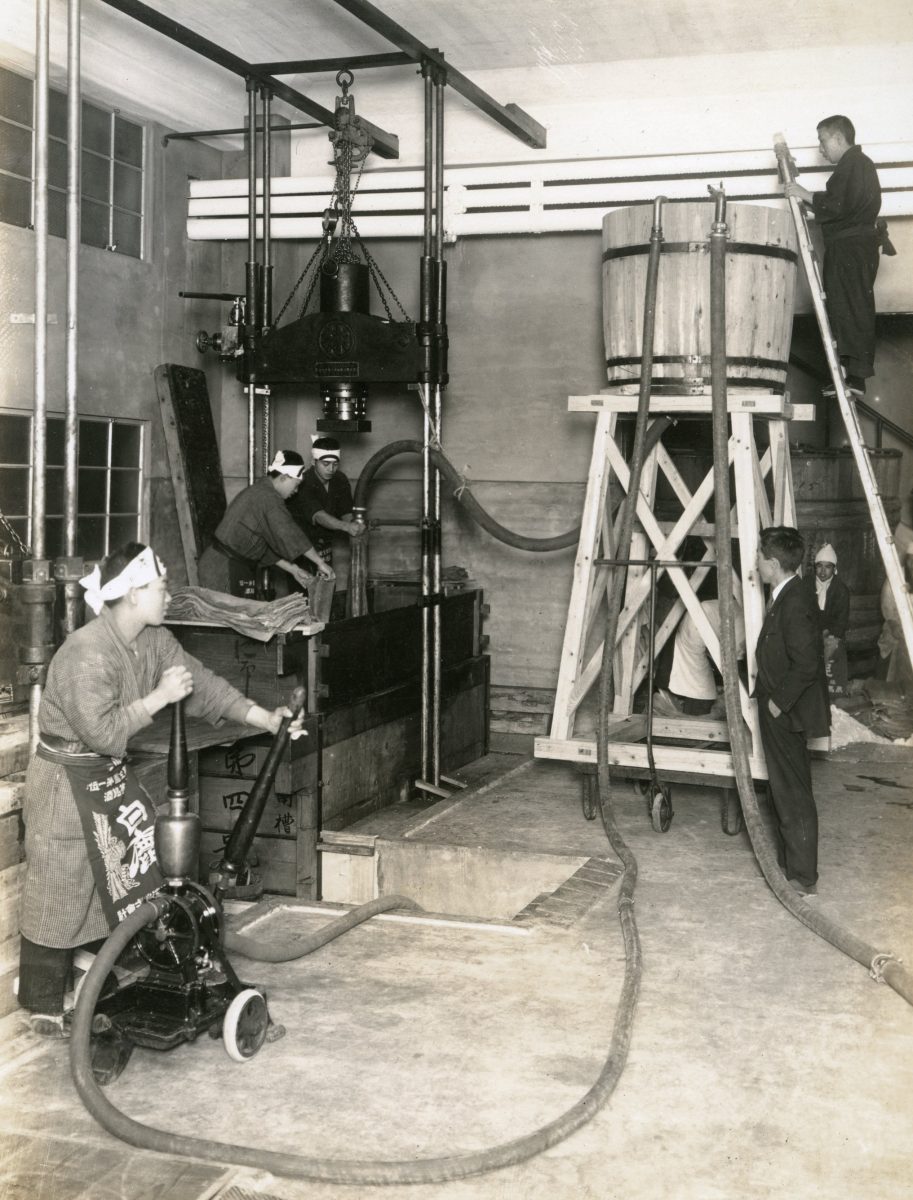

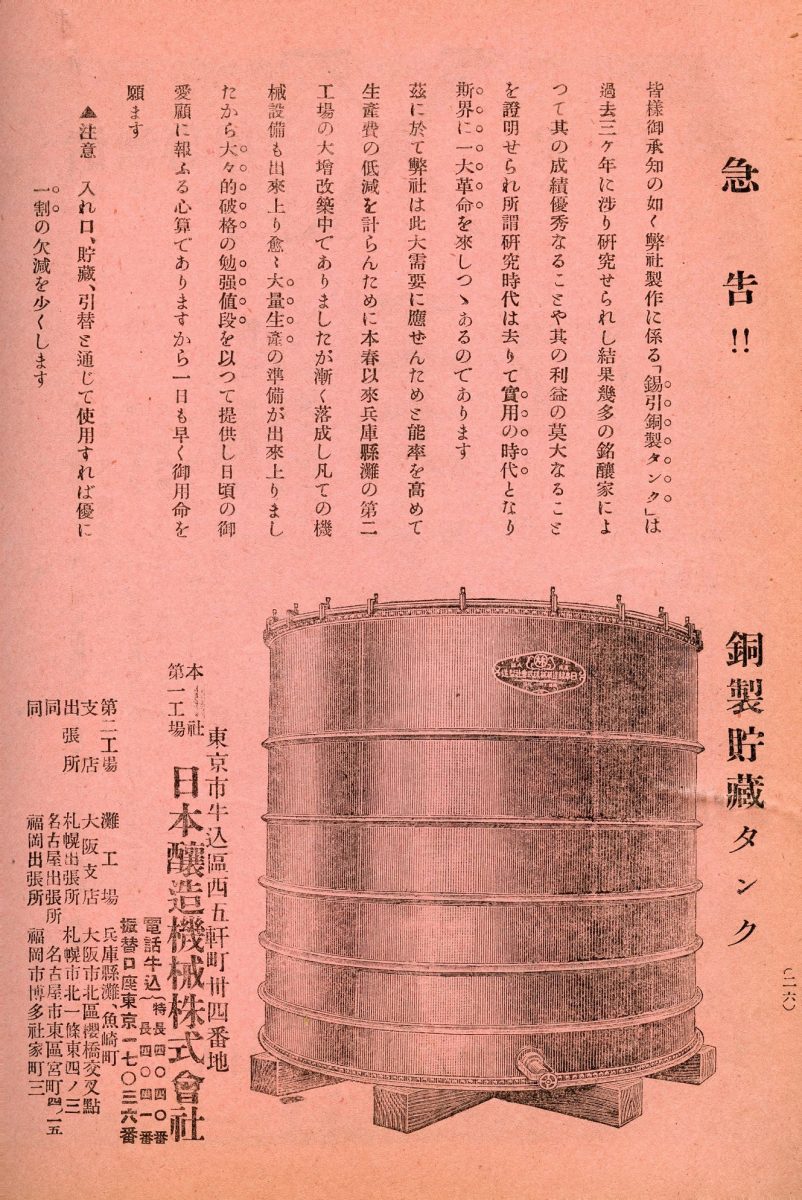

The journal on 1925, there are advertisements of copper storage tanks and hydraulic machines. Copper tanks were invented instead of wooden vats that had been used since the Edo period. Wooden vats were gradually replaced by metal tanks because the wood absorbs sake. When enamel tanks were developed in 1926 and they became popular during the Showa period (1926-1989), copper tanks disappeared. This is because copper was a valuable resource during the Pacific war.

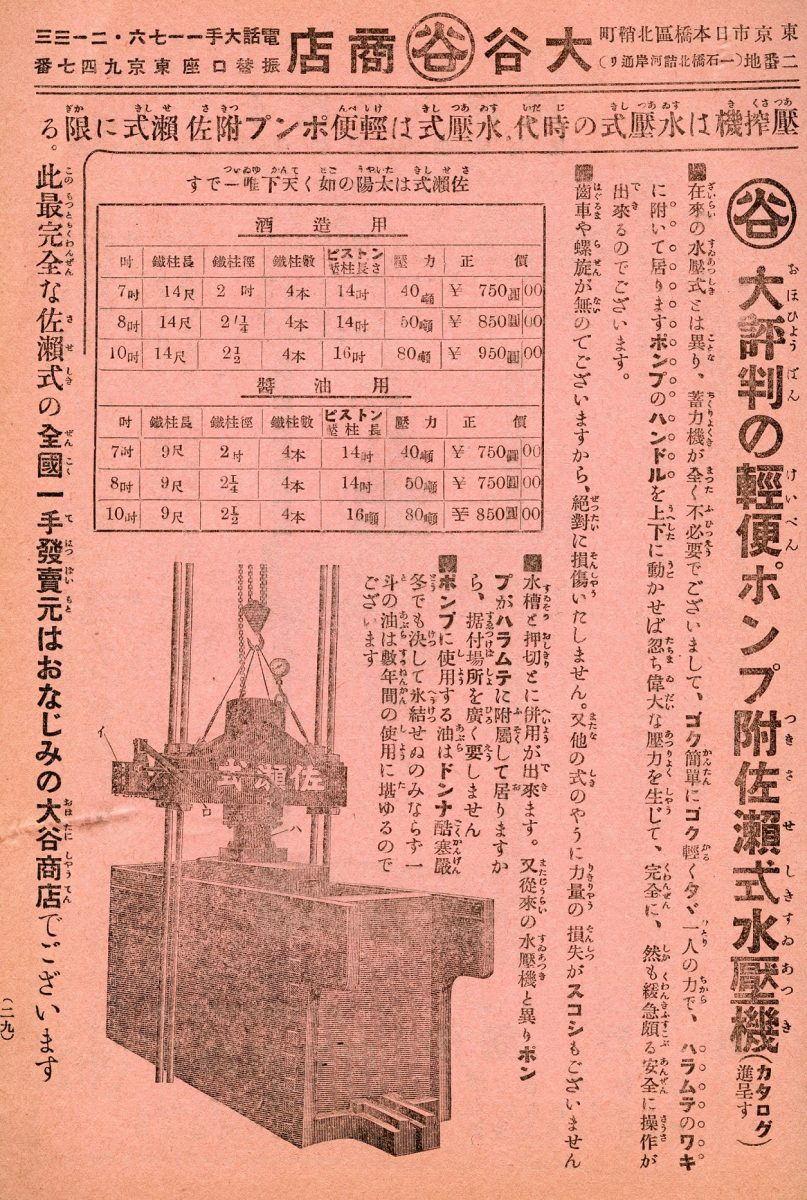

Hydraulic machines were used to press moromi (sake mash) in sakabukuro (sake bag).

In the past, pressure was applied manually, but now using hydraulic machines, we possible to press moromi effectively with less force. After the war, more efficient filter presses were invented and the sake pressing process evolved which needed manpower.

In this way, advertisements of journals are important historical resources to know the transition of wooden sake brewing tools to modern machines. If you are interested in this topic, please come to the museum and see the exhibition. Please look forward to the next article on November 1.

We have to handle raw materials with care!