Hello! This month marks two years since we began writing the “Sake Talk”. Thank you so much for reading the articles!

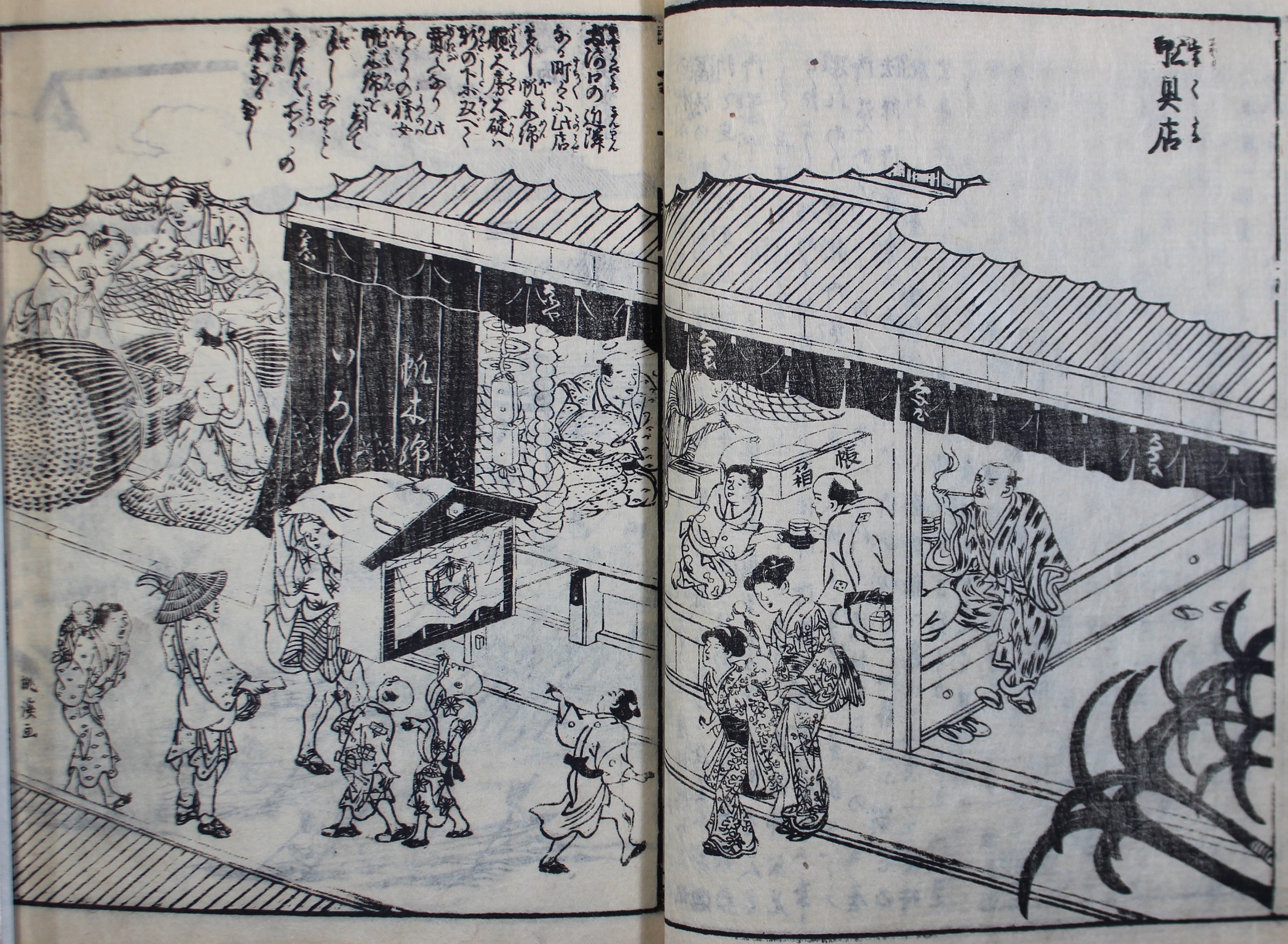

In this post, we’d like to introduce the facilities and functions of a sake brewery building that are depicted in a historical document. Our previous article featured the floor plan of Tatsuuma-Honke Brewing Company’s former main sake brewery building. The facilities pertaining to sake brewing were labeled on the floor plan. “Washing area (araiba)”, “rice steaming area (kamaba)”, “koji room (koji muro)”, and “resting room (kaishoba)” were in the front brewery building, and “pressing area (shiboriba, funaba)” in the large brewery building.

First, let’s focus on the front brewery building. Polished rice was brought to the rice washing area (araiba) and washed to remove bran and dust. Next to the rice washing area was the area where the washed rice was steamed (kamaba). The rice steaming area was a fire-making facility where a cauldron of water was placed on the fire, with a large steamer filled with rice placed on top. The koji room (koji muro) was used to cultivate a microorganism called koji. Koji fungi cannot cultivate well in a low-temperature environment. Therefore, rice husks and other insulating materials were affixed on the ceiling, the walls and the floor of the koji room, and double doors were used at the entrance to keep the room warm like a greenhouse, to allow the koji fungi to multiply well. The resting room (kaishoba) was for the sake brewing craftsmen to eat in and rest. As was introduced in a previous article, Nada sake was made by a group of craftsmen called “Tanba toji” from Tanba region. Because Tanba was far from the Nada region and the craftsmen could not commute, this room was provided for them to stay in during the sake brewing season.

-1-776x1200.jpg)

Next, let’s look at the large brewery building. Most of the large brewery buildings in this region were two-story buildings, while the front brewery buildings were one-story. On the second floor, yeast starter (moto) was made using shallow wooden tubs. Yeast starter making is a process of cultivating the yeast that is required for alcohol fermentation, and was made by mixing steamed rice, koji and water. After the yeast starter was made, it was brought down to the first floor for the next process: main mash (moromi) making. Main mash was made by adding steamed rice, koji and water into the yeast starter on the first, third and fourth days to advance the saccharification of rice starch and alcoholic fermentation. After approximately 20 days, the main mash would be ready to be pressed at the pressing area (shiboriba, funaba), which is shown on the floor plan. The pressing area facilitates a large box-like pressing tool called fune, where sake bags filled with main mash were stacked one on top of the other and pressed to squeeze out the sake. The pressed sake poured into an earthenware pot buried in the ground, and was then transferred to a vat.

Middle: Rice Steaming at Sake Steaming Place “Kamaba”

Right: Yeast Stater Making on the 2nd Floor of the Large Sake Brewery

As we have shown here, large sake brewery buildings were equipped with a variety of facilities and functions. The sake making process has not changed significantly to this day; only the equipment has been mechanized and modernized. At the Sake Museum, traditional sake brewing facilities and functions can be seen in a former sake brewery built in 1869. Please visit the museum at least once! And please look forward to our future articles.

The specialty sake was fully loaded onto the tarukaisen vessels in the Edo period!