Hello! It’s been hot every day. How’s your summer going? We hope you are able to enjoy the hot summer until fall, the season of harvest, arrives.

At the Sake Museum in the Sake Reference Room, our exhibition “Rice Polishing – The First Step in Sake Brewing” is now being displayed. Like last year, this summer we also have quizzes related to the exhibition for you to enjoy, so please visit the museum!

This article features the theme of the exhibition: rice polishing.

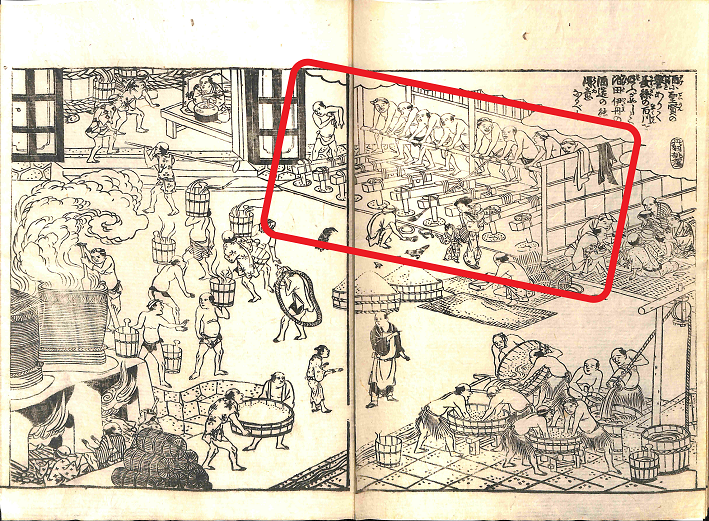

In our previous article, we introduced the history of sake rice. Sake is made from sake rice, and the very first step in sake brewing is called “seimai” or rice polishing. This process polishes off the outer grain of brown rice to expose the inner white part. This practice has continued since the Edo period (1603-1868). A scene depicting foot-powered rice milling in Itami is found in the book “Settsu Meisho Zue (Illustrations of Famous Places in Settsu Province)”. In those days rice milling was called “fumimai” which literally means ‘rice stepping’. This shows that, nationwide, rice was commonly milled through foot-power.

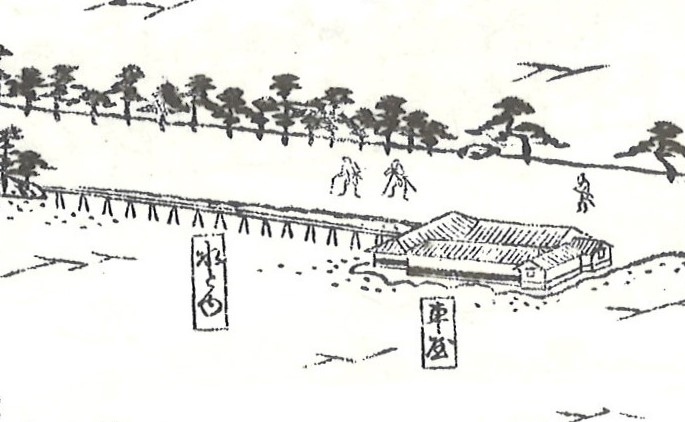

Waterwheel Rice Milling Facility “Kurumaya” and Drainspout “Mizutoi” Connected to Facility from the River

Another well-known method of rice milling in the Edo period was the waterwheel, which became common during the 19th century. Waterwheels were spread throughout the Nada area (eastern part of Kobe City), and later installed near the Shukugawa River, which flows through Nishinomiya near the Sake Museum. The biggest advantage of waterwheel rice milling was it utilized the current of the river, which made it possible to mill a much larger amount of rice compared to foot-power. A historical document from 1888 shows that over 200 mortars were installed in one rice milling location, which proves how effective waterwheel rice milling was.

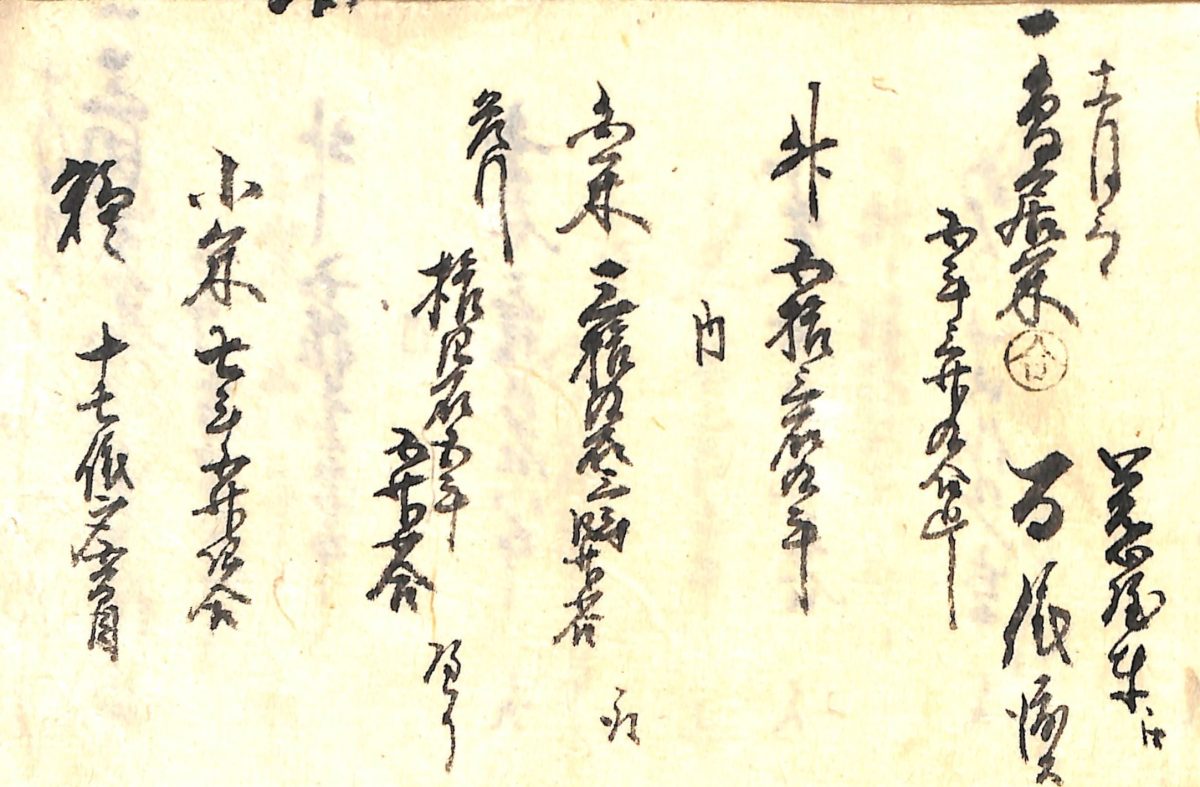

Now, let’s look at the records showing milling amounts by waterwheel. This historical document shows that 53koku 9to (1koku=approx. 180L, 1to=approx. 18L) of Torii-mai rice was milled by waterwheel obtaining 39koku 3to 4sho 5go (1sho=approx. 1.8L, 1go=approx. 180ml) of white rice. This shows that the rice polishing ratio was approximately 72%, but in reality some of the rice was crushed by the pestles, and so the actual rice polishing ratio was said to be approximately 90%.

Waterwheel rice milling continued in the Meiji era (1868-1912). At the same time, more advanced technologies were gradually introduced and adopted.

Our next article will be about modern-day rice polishing. Please check back next month for our new article!

8月2日笹部氏山荘00.01(編集済)-scaled.jpg)

Sake is Japanese Culture!